According to the United Nations Environment Program (UNEP), globalization in the business sector has resulted in an intense growth of the cross border movement of merchandises. The movements have however been disrupted by the current COVID- 19 pandemic. Subsequently we now see an increase in the complication of supply chains of commodities from various countries where different social and economic regulatory frameworks are at hand. There is a need for transparency in the supply chain because of the lack of a common playing field regarding the important aspects of sustainability.

Businesses should care about having green and sustainable supply chains because sustainability it makes business sense. Implementing green supply chains helps companies to combat climate change whilst saving money and attracting new clients. Research has proven that green products are more appealing to clients. Consumers are even boycotting unsustainable products and companies that don’t attempt to achieve sustainability.

A green supply chain is sustainable for future generations and an imperative that will have environmental, social and economic benefits. The way a government procures products and services has a large impact on an economy’s social and ecological footprint. Many businesses, consumers and stakeholders are becoming more involved in the growing green movement. Businesses are trying more and more to make their supply chains greener by introducing sustainable strategies throughout their organizations and supplier relationships. This is due to influence by customer loyalty shifting towards environmentally friendly products.

The Harvard Business Review (HBR) mentions that a rising number of Multinational Corporations (MNCs) have pledged to work only with suppliers that adhere to social and environmental standards. Naturally these Multinational Corporations will expect their first-tier suppliers to comply with those standards. These MNCs ask that suppliers ask for compliance from their suppliers who then also ask the same from their suppliers. The intention is to create a smooth surge of sustainable practices throughout the Supply Chain Network (SCN). The recent focus on sustainability has resulted in a growing need for integrating environmentally safe choices into supply chain management practices.

The model of Green Sustainable Supply Chains involves using environmentally friendly inputs and converting them through change agents into outputs that can be regained and re-used at the completion of their lifecycle. This cycle creates a sustainable supply chain. Green and sustainable supply chain are implemented to reduce costs while helping the environment. Sustainability is a much broader term which considers implications of those products and services used over a much longer period of time. Green supply chains on the other hand, refer to the raw material eco-friendliness, the manufacturing process, products and services of a certain supply chain. It also gives emphasis to environmental compliance and executes supply chain management functions through business partner collaboration and operational management.

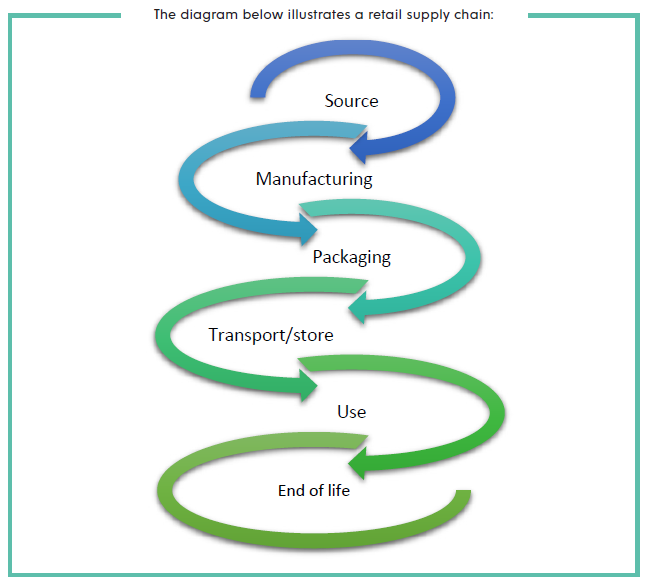

The diagram below illustrates a retail supply chain:

Over the years, there has been growth in the need for greener technologies. Businesses have to adapt to new times and go green. Digital Capability in the green supply chain gives businesses visibility from end to end. Going green is more than using recycled paper and energy-efficient light bulbs but involves changing the supply chain to portray a much greener image. Companies can benefit a lot form implementing a green supply chain and there are various ways this can be done.

A green supply chain can be implemented in the service sector for companies like news organizations, accounting firms and consulting companies. Service-based firms can reduce the amount of paper they produce, cut back on the amount of plane travel and even reduce the number of workers that drive to work. These companies can also reduce, re-use and recycle their waste products. These measures will reduce their impact on the environment by producing less waste and lowering greenhouse gas emissions. Manufacturing companies can create a green and sustainable supply chain through adopting a circular economy which means less impact on the supply chain and reduced demand for raw materials. Companies can implement the green supply chain to combat climate change, save money and attract new clients.

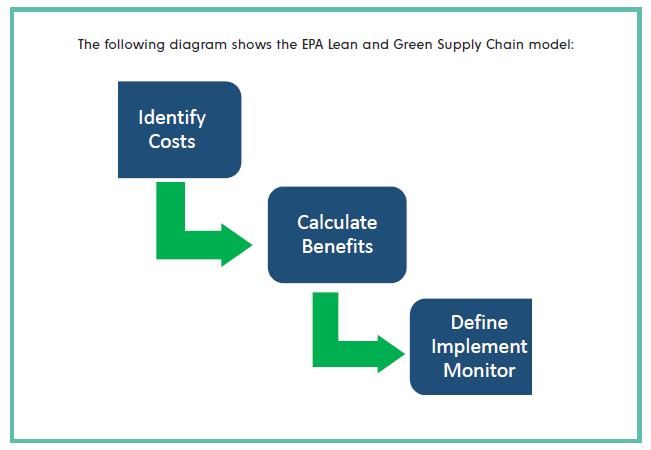

The following diagram shows the EPA Lean and Green Supply Chain model:

The model illustrates a four-step framework. This is used to identify and use environmental information to improve financial performance whilst greening the supply chain:

- Identify costs

- Determine opportunities

- Calculate benefits and

- Decide, Implement and Monitor.

Significant management aspects being emphasized are the requirement for integration of environmental considerations into each and every core industry program and the need for tools to monitor and benchmark the results. A Green Sustainable Supply Chain integrates environmental factors and supply chain management principles to identify the ecological impact of an organization’s supply chain processes. Many businesses are now seeking out solutions and guidance on how to implement a sustainable supply chain because they are now aware of the importance of this integration to enable a sustainable business strategy. The sustainable supply chain is no longer solely about green issues, but also about generating efficiencies and cost containment.

United Nations Environment Program (UNEP) states that Sustainable Public procurement (SPP) is increasingly being used as a means for governments to transform markets and transition towards a greener economy. SPP plays a very important role in promoting the dissemination of sustainable production practices through supply chains. It has the potential to promote the improvement of companies’ performance along supply chains, including small and medium-sized enterprises. According to UNEP, companies including small and medium-sized enterprises are already taking advantage of these opportunities for innovation by positioning themselves as leaders in sustainability, gaining a competitive advantage in the market of Sustainable Public Procurement.

Goal 12 of the United Nations Sustainable Development Goals (SDGs) was set to ensure Responsible Production and Consumption patterns. The United Nations defines the Marrakech Process as a global multi-stakeholder process to support the implementation of Sustainable Consumption and Production (SCP) and to develop a Global Framework for Action on SCP. The United Nations further states that SCP also improves the management of natural resources, and aids countries and businesses delink economic growth from environmental degradation. The Marrakech process stipulates that sustainable products should promote sustainable and efficient management of resources through the whole life cycle, and in all stages of the supply chain of goods and services. SCP is an opportunity to leapfrog to more resource-efficient, environmentally-sound and competitive technologies whilst promoting resource and energy efficiency, sustainable infrastructure, and providing access to basic services, green and decent jobs and a better quality of life for all. Companies of different sizes are responsible for the delivery of goods and services, and thus also for the management of supply chains.

Ethical, environmental and social issues have to be dealt with in order for the green supply chain to become more sustainable. There needs to be continuous improvement in aspects of supply chain.